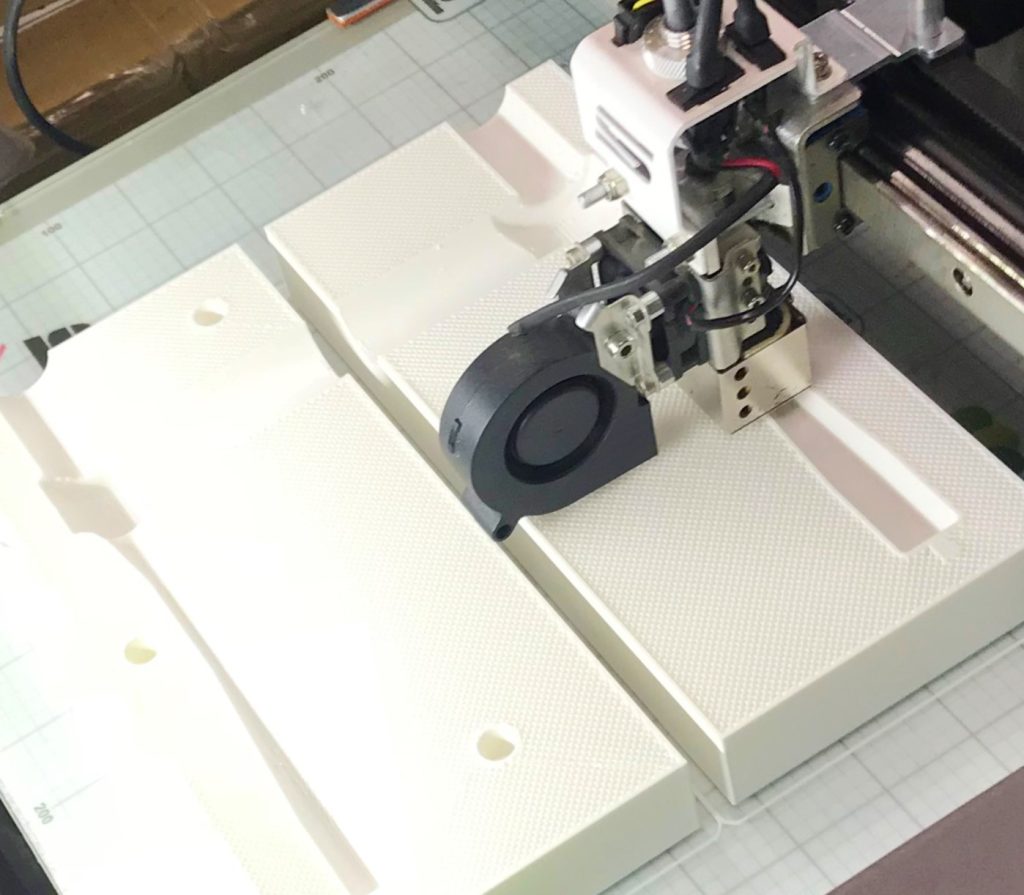

The innovation of 3D printing has revolutionized the sand casting process. Forward-thinking foundries are using this technology to produce polymer patterns and sand molds and cores.

Ideal for low-volume casting needs, both types of tooling offer the following benefits:

– Streamlined casting process

– Potentially lower cost than traditional tooling

– Reduced production lead time

– Ability to bring your product to market quickly

– Greater design flexibility

– Capability to support intricate designs and complex geometries

There are several considerations when deciding whether this technology fits your casting needs. For example, a model is required and there may be size limitations. Additionally, if your parts have complex cores that require specialty sands or core wires (i.e. those with thin core passages), traditional tooling may be more suitable for your process.

We know having a multitude of options is a positive industry development, and it can also be overwhelming. Our team of dedicated engineers is happy to work with you to help identify whether rapid response technologies can enhance your casting manufacturing experience. To learn more about how Badger Alloys’ 3D technologies can reduce the lead time and capital costs involved with your casting production, please contact us for more information.