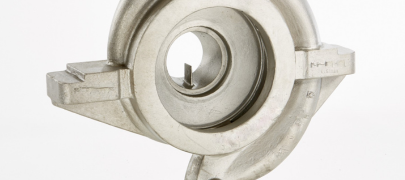

At Badger Alloys, we offer more than 200 sand casting alloys for your project. Our capabilities allow customers to house multiple projects with one sand casting manufacturer, minimizing the need to move casting patterns and thus increasing job efficiency. Sand casting alloys poured routinely on site include: High Alloy/Stainless Steel, Bronze and Copper-base Alloys, Brass Alloys, Carbon/Low Alloy Steels, Nickel-base Alloys, Wear-resistant Alloys.

All our materials are in compliance with Dodd-Frank Conflict Minerals regulations. They are organized through a computerized metal inventory system and stored in a dedicated facility. We use all pure raw materials and remelt stock. Our dedicated laboratory staff specializes in a wide range of materials, designs and end uses. They have experience in the design, melting, heat treatment, processing and analysis of hundreds of ferrous and nonferrous alloys.

Every industry demands specific casting requirements to ensure performance at the highest level. Our Alloy Search lets you browse our wide variety of sand casting materials and find your matched strength for properties like:

Have questions about our alloys? Request a Quote. We will respond shortly!

High alloy and stainless steel alloys are high-value alloys that are suitable for many applications.

Read More

Badger Alloys offers a variety of bronze and copper-base alloys to meet your metal casting service needs.

Read More

Brass alloys are popular for their corrosion resistance, particularly in sea water and other water service applications.

Read More

As industry-leading non-ferrous cast steel and carbon steel casting manufacturers, Badger Alloys offers a wide variety of low alloy steels to suit your project requirements.

Read More

Nickel-base alloys are most often alloyed with a particular element to impact certain properties.

Read More

Wear-resistant alloys are used primarily for their resistance to oxidation and impacts of certain gases.

Read Moresubmit a request for a proposal or quote