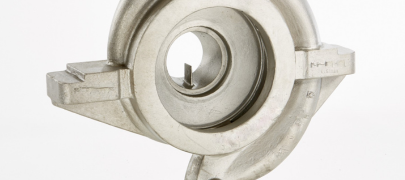

Badger Alloys offers a variety of brass alloys — like C87500 (C69410) — to meet your sand casting service needs. We pour a uniquely wide variety of alloys on site, including high alloy/stainless steels, bronze and copper-base alloys, carbon/low alloy steels, nickel-base alloys, and wear-resistant alloys. Because of the wide variety of alloys poured at Badger Alloys, OEMs view us as a “one-stop shop” to meet all their valve and pump equipment needs. That means OEMs can have all their pump and valve equipment needs met on our manufacturing campus in Milwaukee; there is no need to move tooling and pattern equipment to multiple foundries.

Silicon brass alloys, among our most popular materials, provide good resistance to corrosion in brine applications. Our wide variety of furnace shells affords us tremendous operational flexibility, allowing us to dedicate one furnace solely to silicon brass. This drastically reduces our lead times for this material versus other foundries.

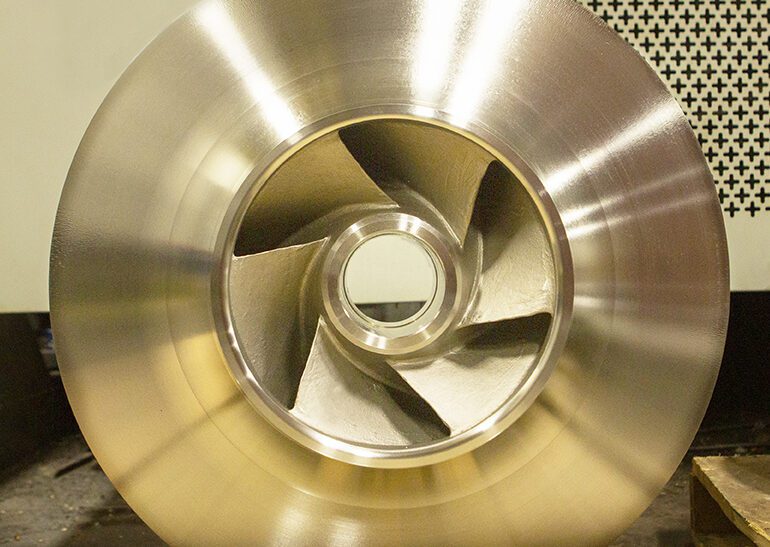

Silicon brass is excellent for parts that are used in water/salt water. They are highly resistant to corrosion in briny applications, making this alloy a particularly good choice for impellers used in the marine industry.

Silicon brass alloys are commonly used for:

Ready to get started? Request a Quote. We will respond shortly!

High alloy and stainless steel alloys are high-value alloys that are suitable for many applications.

Read More

Badger Alloys offers a variety of bronze and copper-base alloys to meet your metal casting service needs.

Read More

As industry-leading non-ferrous cast steel and carbon steel casting manufacturers, Badger Alloys offers a wide variety of low alloy steels to suit your project requirements.

Read More

Nickel-base alloys are most often alloyed with a particular element to impact certain properties.

Read More

Wear-resistant alloys are used primarily for their resistance to oxidation and impacts of certain gases.

Read Moresubmit a request for a proposal or quote